Basic equipment

- Robot: KUKA AGILUS-2 with 2 × 5/3 valves

- Valve extension on robot: 2 × 3/2 valves

- Safety door and step simplify access to the robot and injection molding tool

- Control cabinet and robot controller are integrated in the cell

- Basic plug-in unit consisting of a milled aluminum plate with prefabricated threaded holes for easier integration of peripherals such as vision sensor, ionizer, etc.

- Operation and fault indication via hardware keys and with integrated visualization on the KUKA Smart PAD

- Manual control box for the operator side of the injection molding machine

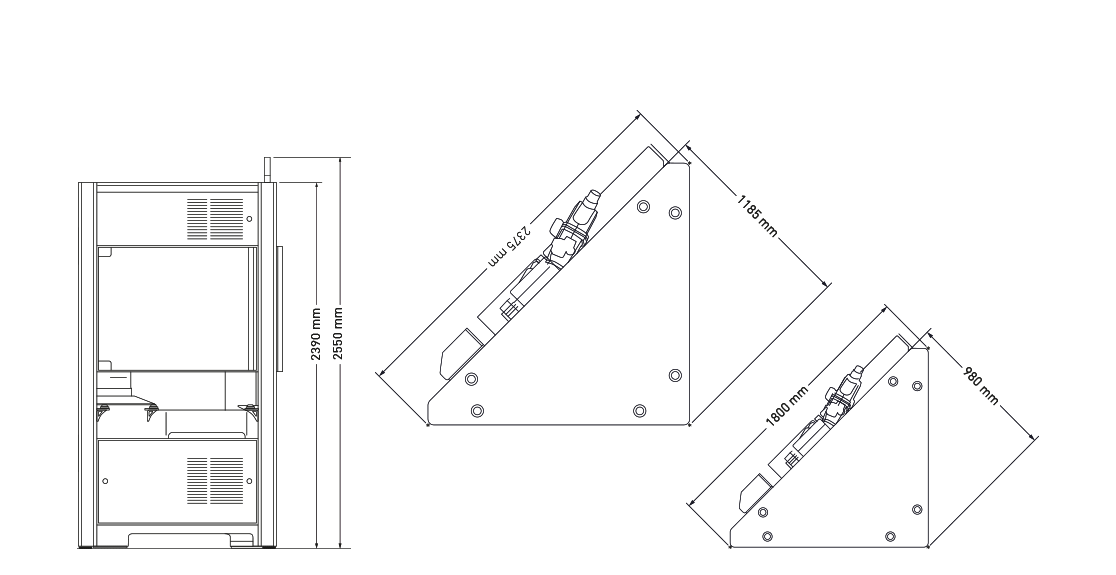

- Transport of the cell is possible with a lift truck

- Connection via Euromap 67 and 73 to injection molding machines

Options

- flexobot+ (30% larger)

- Product-specific grippers

- Increased mobility through air cushion system

- Semi-automatic calibration of the robot

- Option shafts for product-specific applications

- Service option via remote maintenance

- Special paint for robot and cell

- Integrated inspection via vision sensor or camera

- Reduction of electrostatics by ionization

- Customer-specific plug-in units for complex applications