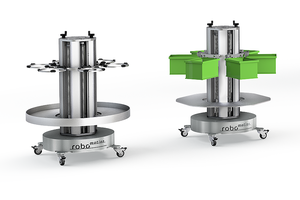

The highest level of flexibility

Are you looking for an automation solution for small production quantities and frequently changing products?

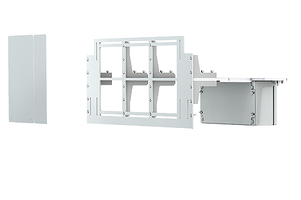

Our solution: A flexible robot cell that can be adapted to your order. A wide variety of applications can be implemented quickly and cost-effectively using plug-in units that are easy to exchange. Due to its space-saving shape and the possibility to easily move the robot cell, the flexobot can be used flexibly on different injection molding machines.

Insertion and removal or the whole package?

With our different options, the flexobot is up to any task. The possibilities range from the insertion of parts for overmolding, the removal of finished parts to the assembly of complex assemblies. The aim is to complete the production process including quality testing in the flexobot.

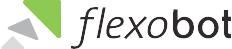

Basic module

Air cushion system

Enables easy positioning of the flexobot without a lift truck. The flexobot can be easily moved by hand using the air cushion system in confined spaces.

Option shafts for product-specific applications

Q-shot, NOK parts, sprue, finished parts, infeed of insert components.

Plug-in unit for applications

Offers basic equipment for possible material flows from or into the flexobot.

Gripper

Individually designed grippers for your application (e.g. vacuum technology, lightweight construction).

User Interface

Simple operation using modular software.

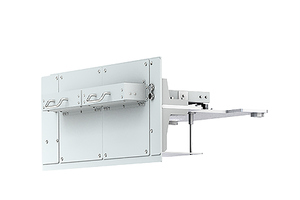

Trunk slide

Parts can be ejected directly from the safety area of the robot. A box holder can be integrated as an option.

NOK-Box

It is adapted to the interior contour of the flexobot. Ideal for ejection of sprues and rejects.

Manual control box

For easy operation of the flexobot from the operator side of the injection molding machine.

Packaging carouse

The packaging carousel can be individually adapted to your desired container.

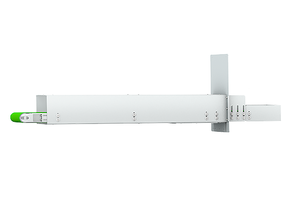

Conveyor

Enables the careful depositing and transport of finished parts.